Inside the Black Box: Why LiThink’s 10-Year Warranty Begins with Real Cell Compression, Not Tape

LiThink's new LiFePO4 battery series features an automotive-grade Alloy Internal Frame, backed by an industry-leading 10-Year Warranty.

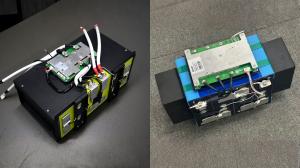

The LiThink battery architecture (left) utilizes a rigid Alloy Internal Frame for stability, whereas standard market alternatives (right) often rely on simple adhesive tape.

The core of LiThink's durability: A rigid automotive-grade alloy internal frame designed to maintain constant compression on prismatic cells, effectively counteracting natural swelling over the battery's lifespan.

LiThink replaces adhesive retention with a rigid Alloy Internal Frame to counteract cell swelling and ensure true 10-year stability.

BERLIN, GERMANY, December 30, 2025 /EINPresswire.com/ -- LiThink today published a technical overview of the internal architecture used across its European LiFePO₄ battery lineup, focusing on an aspect that is rarely explained in consumer-facing materials: how prismatic cells are mechanically restrained over time. The company stated that its 10-year warranty strategy is tied to a verifiable engineering principle—consistent structural compression and controlled restraint—rather than relying on warranty wording alone.In LiFePO₄ battery packs, the “black box” is not only the electronics. It is also the mechanical system that keeps cells in a controlled state through years of cycling. Prismatic cells can experience gradual dimensional changes during long-term operation. If a pack relies mainly on adhesive-based or soft retention methods, the retention approach may not be designed to maintain controlled, long-term compression as conditions evolve—particularly in demanding applications such as RVs, marine installations, and off-grid systems.

“Warranty only becomes meaningful when it is supported by design choices customers can understand and verify,” said a LiThink technical spokesperson. “For long-term service, the question is simple: what physically maintains cell restraint after years of cycling?”

Why compression matters: in prismatic packs, longevity is also mechanical

Battery longevity is often discussed in terms of chemistry, cycle counts, and BMS protections. In prismatic-cell packs, there is an additional reality: longevity also depends on mechanical restraint.

A long-life pack architecture should be designed to:

maintain cell positioning and restraint over extended service life,

reduce mechanical drift and stress concentrations over time, and

minimize friction or contact points that could become wear mechanisms as the pack ages.

LiThink stated that its internal architecture is designed with this mechanical constraint in mind, rather than treating retention as a purely assembly-oriented step.

What LiThink is showing: three structural elements intended for long-term restraint

LiThink highlighted three internal design elements that it considers central to its long-life architecture:

1. Alloy Internal Frame: defined restraint and compression by structure

LiThink employs a high-strength alloy internal frame intended to provide a rigid retention system for the cell stack. The goal is to maintain a consistent mechanical environment where restraint is defined by structure—not by materials whose holding characteristics can change over time.

2. Six-Sided Epoxy Insulation: isolation as an architectural choice

LiThink uses a six-sided epoxy insulation strategy designed to improve internal isolation and reduce risk at potential contact points as the pack ages. LiThink notes that isolation is not only an electrical consideration; it also supports stable long-term mechanical interfaces inside the enclosure.

3. Wear-point prevention: routing and fastening discipline

LiThink also points to protective routing and fastening concepts intended to reduce common wear points, including cable abrasion and long-term loosening risks at internal interfaces.

LiThink stated that these are not abstract claims and can be referenced through published internal structure visuals and technical descriptions.

Why this matters in European RV, marine, and off-grid use

LiThink noted that European long-life expectations are tied to real system demands:

RV systems face frequent daily loads and long service life expectations across seasons.

Marine systems operate in humidity- and corrosion-prone environments.

Off-grid systems often require deeper cycling patterns and predictable performance over time.

In these contexts, LiThink stated, a long warranty is meaningful only if the design addresses the failure modes that matter over years—not only electrical protections, but also the mechanical conditions supporting stable cell restraint.

A practical comparison checklist for buyers

LiThink recommends evaluating “long-life” claims using criteria that can be discussed and compared:

Compression / restraint method: Is there a rigid structure intended to maintain restraint long-term, or is retention primarily positional?

Isolation strategy: Is there comprehensive internal insulation designed as part of the architecture?

Transparency: Does the brand disclose internal structure visuals and explain the rationale behind them?

Policy clarity: Are warranty terms published in a clear, referenceable format?

Availability

LiThink’s structural overview and internal component visuals are available for download in the official Media Kit.

For complete details on terms, scope, and exclusions, please refer to the published Warranty Policy.

About LiThink

LiThink develops LiFePO₄ energy storage solutions for RV, marine, and off-grid applications across Europe. The company focuses on engineering-led design, verification-led development, and transparent policies intended to reduce uncertainty for end users and installers.

Media Contact

LiThink — Press & Communications

PR: pr@lithink.de

Website: www.lithink.de

Levi Chandler

LiThink

pr@lithink.de

Visit us on social media:

Instagram

Facebook

YouTube

TikTok

X

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.